Receipts

Files Associated with Receipts

Working with Receipts

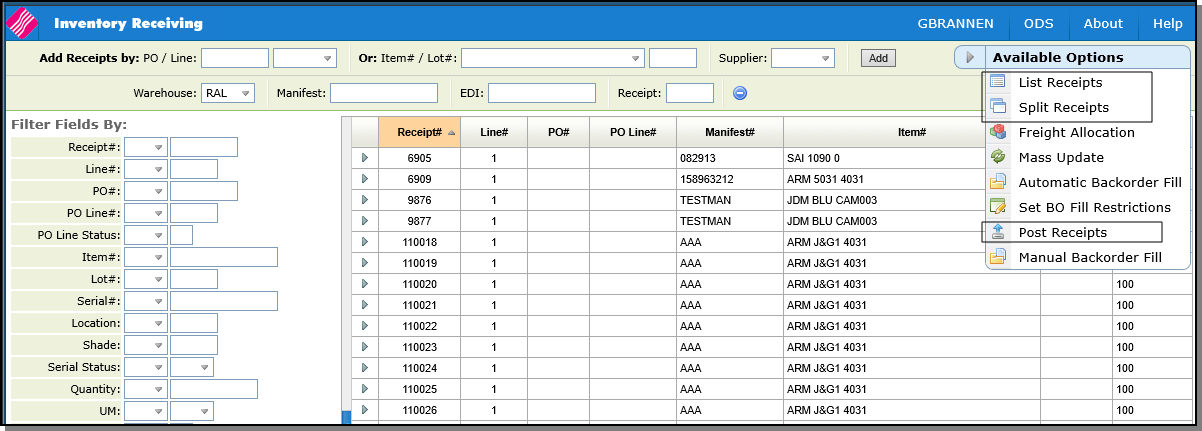

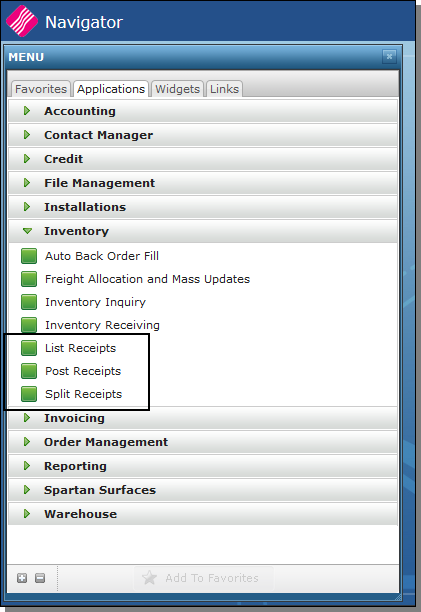

The options for working with receipts are found in the Available Options drop down.

And from the initial Navigator menu.

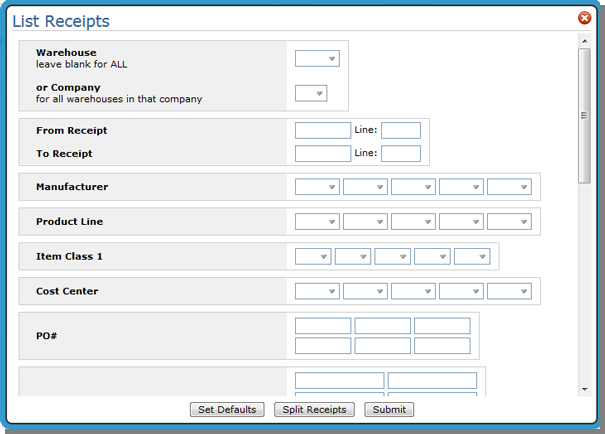

List Receipts

The Receipts List does the following:

- Shows the number of serial numbers included within each subtotal.

- Shows the supplier number.

- Observes warehouse and company number security restrictions, if any, as entered into the Control Panel. Workstations can be restricted to specified warehouses and company numbers in the Control Panel.

- Sort options by other reference number and serial number.

- Prints Put-A-Way Sheets, for warehouse to assign warehouse bin/locations.

- Requests serial number tags from Receipts List option, in card stock or bar coded format.

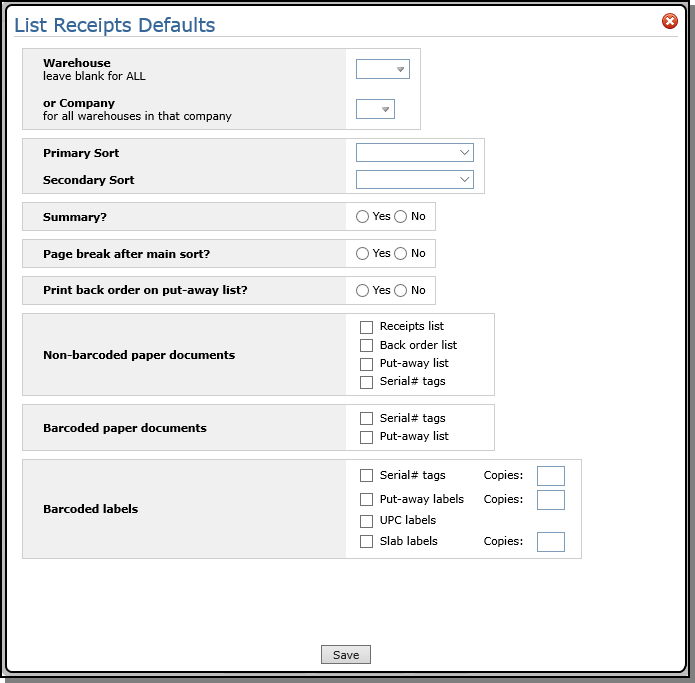

Decide if you want a Summary or detail listing. In the summary version, only sub and grand totals are listed. No details print.

Enter Y in the Page break after primary sort option to start a new page for each main sort. For example, if your main sort is by manifest, the listing starts a new page for each manifest.

The following document options are available:

Non Barcoded Paper Documents

- Receipts List - A list of all receipts entered. When the receipts are listed, freight charges and any rebate charges are added together and listed as one.

- Back Order List - A list of all open back orders that are for items being received.

- It shows the Order Handling Code for each back order.

- It shows the initials of the order entry operator that originally entered the back order.

- Shows the customer purchase order and/or job name if there are no comments entered in the Other Ref#/Comment field on the Back Order Fill Screen.

- It notates back orders that are on "fill/Kill" orders that have been shopped and run through the close-a-truck procedures. These back orders cannot be filled since "fill/kill" means you ship once and cancel what remains. This warning will occur only when you have: Partially shipped a fill/kill order and When prior to updating invoices via the night jobs, one or more of the unshipped items is received through the Pre-Receipts and Back Order Fill System. This method prevents needlessly filling a back order that was effectively canceled when other parts of the order were shipped even though they are not yet invoiced.

- Serial# Tags (On paper/card stock) - Inventory tags for each serial number. Primarily for rolled goods.

- Put-Away List - A list of all receipts with space for warehouse personnel to fill in the bin/location.

Barcoded Paper Documents

- Serial# Tags (Barcoded on Paper) - This option is a full 8 1/2 by 11 inch tag meant to print on laser paper, and can be inserted into a plastic or laminated slip case. This format takes advantage of the high resolution of the laser printer, and prints bold letters, numbers and a large barcode. In order to use this new label, your printer must be an IPDS printer, and you need printer Services Facility/400 installed.

- There are several serial tag formats available. The formats are controlled via option 3 - Label Styles File on the EDI and Bar Code Functions Menu (EB) menu.

- Bar Coded Put-Away List - Showing back orders.

Barcoded Labels

- Serial # Tags (On bar coded labels) - Bar coded inventory tags for each serial number. Primarily for rolled goods.

- Putaway Labels - Includes the serial number, PO number, Item number, receipt and line number, and quantity.

- UPC Labels

- Slab Labels - This label is generated using a Zebra label printer that can print small bar codes.

The Set Defaults option allows you to set defaults that apply, unless overridden.

- One option on the Default Parameter screen, Print back order on put-away List, gives you the option of printing back orders on the put-away list. If this option is activated, then any back orders for the received items are printed under the items. This facilitates "cross docking" opportunities so that material can be staged to fill the back order instead of being put away.

Split Receipts

Use this option to split all the receipts by warehouse, receipt range, or manifest. For example, if four pallets came in on a receipt, this functionality can be used to split one receipt into four to help with moving and storage.

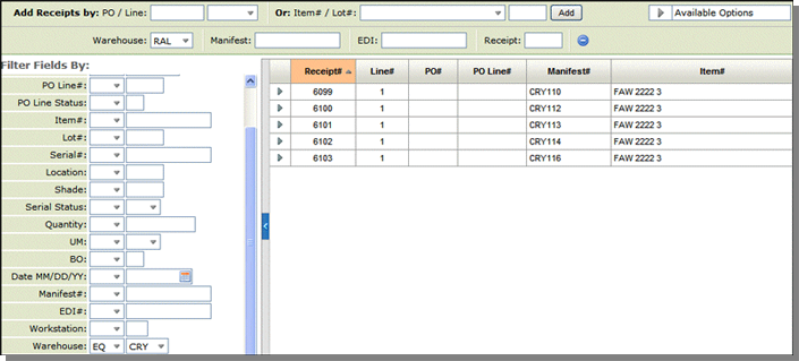

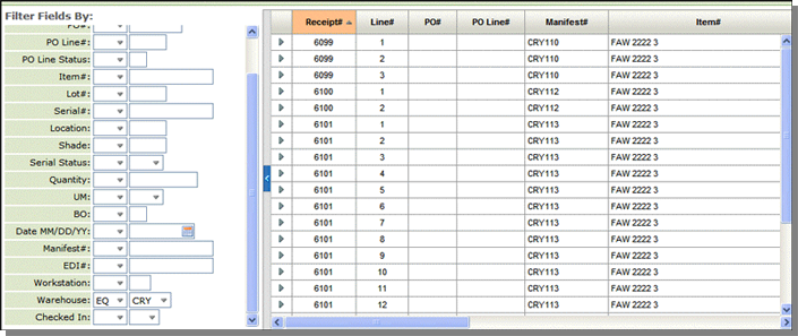

As an example of this functionality, consider the pre-receipts for warehouse CRY.

When Split Receipts is selected and a receipt range is entered the system looks for receipts that meet the criteria:

- UM is PA (pallet)

- Items on the receipt have a conversion from the received UM to pallet (UM conversions are shown in the lower right-hand corner of the update screen).

- The amount received will make more than one pallet.

When the receipts are split, the pre-receipts increase.

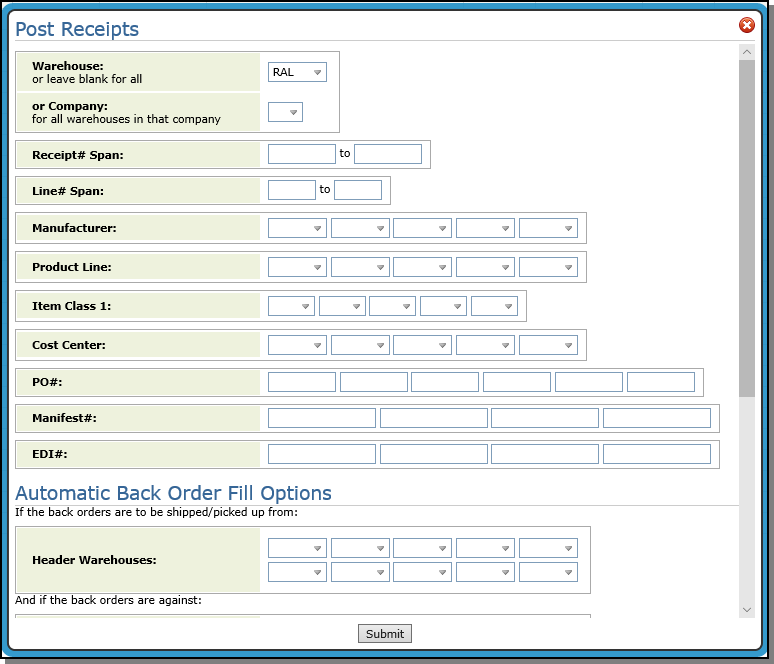

Post Receipts

This option lets you post receipts and automatically fill any back orders waiting for the inventory contained in the receipts. If you fill back orders with this option, no changes can be made except for Allocation Processing.

- Enter a specific warehouse or a whole company to run the posting for.

- You must enter one the following: manifest number, receipt number, EDI number, manufacturer, or purchase order number.

- If you choose to post by receipt, you can post a span of line numbers instead of the whole receipt.

Click Submit to post the receipts to inventory and automatically fill any back orders.

For more information on Automatic Back Order Fill, click Receipts.

Files Associated with Receipts

Green Screen

- Inventory Receipts (pre-receive and back order fill) Menu - INB

- Inventory Receipts by Item Number - INV 5

- Print Receipts Register - RPO 2

- Print Receipts Status Report - RPO 10

- Print Inventory Receipts Analysis - RPO 14

- Receiving Inventory with IWMS

System Wide Settings (SET 4)

- Serial Number Assignment - allows you to automatically assign a serial number to inventory during receiving.

- Unavailable Serial Number Ranges - Specifies the ranges of serial numbers the system should bypass if the automatic serial number assignment is active.

- Options for Inter-Company Receipts

File Maintenance Files

- Stock Keeping Unit File - warehouse locations entered here appear on the receiving screen.

- Manufacturer File and Product Line - Contain settings for generating unique serial number prefixes and suffixes and for creating a default serial number to use for items received from this manufacturer or in this Product Line.

- Packaging File - Conversion information is pulled from the Packaging File. Use the Packaging Class field in the Item File to find the packaging class for an item.

- Cost File - The cost class (as identified in the Item File for the item) provides the base and freight cost. If a Freight Cost Override Table is specified in the Cost File (via the Frt Tab# field in the lower right-hand corner), that freight table overrides the freight cost entered in the Cost File. Freight Cost Override Tables are accessed via menu option SET 9.

Warehouse Settings File (SET 14)

This program enables you to set warehouse level options. The settings that affect receiving are:

- Use Extra Receiving Features - This setting must be active to use of any of the next four table options on this screen. If this option is activated, information from any of the following four tables, if activated, shows up on the Enter Receipts Screen (INB 1).

- Use Additional Freight Table

- Use Currency Exchange Rate Table

- Use Duty Table

- Use Expected Supplier Rebate Table

- Manifest Number Required during Receiving

- Allow receiving system to use Lot# for other than special orders? - This option allows you to prevent the entry (accidental or otherwise) of lot numbers other than those used for special orders. If a user tries to receive or adjust a lot number other than a special order lot number, the system issues the appropriate error message and prevents the entry. It is recommended you enter N here, unless you use the lot # field for orders other than special orders. Do not confuse lot number with serial number when making this decision.

- Allow override of freight from freight tables in receiving program - This field, if activated, allows users who are authorized to access costs to override freight table costs. This option applies to freight costs derived from Freight Cost Override Tables. When using standard freight costs, any user authorized to adjust cost can override costs. If this option is set to N, the freight table must be updated in order to change freight costs in the Receiving Program.

Supplier Rebates Table (SET 10)

- The Supplier Rebate Table allows you to mark up and mark down your inventory value for margin purposes. This markup is kept separate from the base cost. It is recorded separately and posts to your choice of general ledger accounts.

- Marking up inventory value provides a means to equalize big purchasing discounts against what is paid out in salesman commissions. For example, you may purchase a special container of wood at a steep discount, but instead of showing large increases in margin and commissions, you may prefer to move the affect of the discount to another part of your financial statement such as "special purchasing discounts".

- A negative rebate percentage adds to the inventory receipt value and a positive percentage reduces the inventory receipt value. This increase in cost is added during receiving, and reported in the separate rebate column of the receiving reports.

Inventory To G/L Interface File (ACT 103)

- This file maps the Suppler Rebate for posting to the correct Chart of Accounts.

Print Inventory Registers

- Rebate costs are separated when running the 198 column detail report for receiving and posting to GL.