Open Order Reports - Menu Option ROO

Use this menu to list orders within specified date ranges and for specified categories and parameters. Although the menu is titled Open Order Reports, you can also specify to include closed orders, in order to print a historical log of orders. Many Exception Reports can be generated, including All Orders That Have Been Picked But Not Billed.

The Open Order Reports menu is accessed via menu option ROO.

- Open Order by Item Report (ROO 2)

- Open Orders By Ship Date Report (ROO 3)

- Open Orders by Supplier (ROO 7)

- Open Orders Aging Reports (ROO 10)

- Order Expediting Report for Cash/COD Orders (ROO 12)

- Order Notepad Analysis (ROO 13)

- Open Order Report for Customers (ROO 14)

- Holds, Quotes and Unprocessed Orders Reports (ROO 15 and ROO16)

- List Back Orders That Can Be Filled From Available Local Stock (ROO 17)

- Four-Way Order Analysis Report (ROO 18)

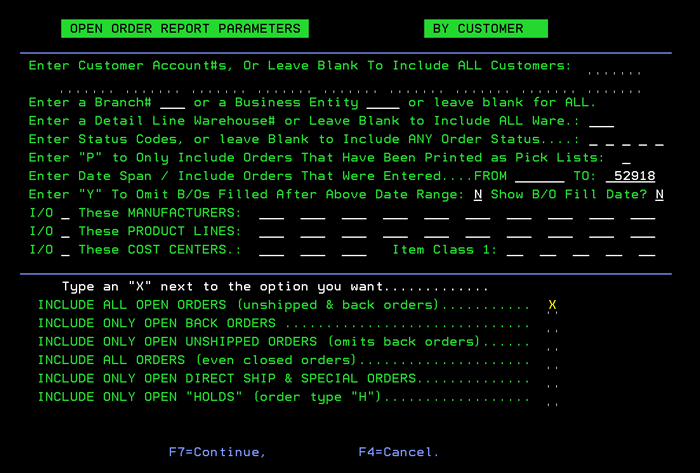

The first screen to appear when any Open Order Report option is selected allows you to select the parameters to include on the report.

Select your report parameters and press Enter then F7 to proceed through the report generation process. If a user is restricted to a business entity, the business entity automatically appears, and may not be changed. You can enter a ? to see a list of all the business entities. An example report is shown below.

In the middle of the screen are four include/omit fields. Enter an O, in the appropriate field to omit a manufacturer, product line, cost center, or item class. To include parameters, enter an I. The default for the I/O field is to be blank. If you make an entry into the I/O field you must enter at least one value in the corresponding category or you will receive an error message. Also note that Cost Centers and Item Classes are controlled together by a single I/O option.

The bottom portion of the screen lets you decide the type of orders to include. If you choose to include closed orders, the totals are calculated as follows:

- Open orders as well as invoiced orders are included in the totals.

- Canceled orders, although they are also considered closed, are not included in the totals.

To conduct a search of the four fields, enter a ? into the field and then press Enter.

Open Order by Item Report (ROO 2)

The Open Order by Item Report, accessed via option 2 on the Open Order Reports Menu, highlights unusual sales. All unusual sales are flagged by the message Unusual Sale, followed by the order type U or V. Order type U is an unusual sale that is not counted toward average usage when reordering stock. Order type V is an unusual sale that is flagged, but still counted toward average usage when reordering stock.

The Open Order by Item Report also shows:

- Operator's initials for each order

- If order is on credit hold

- Total onhand, scheduled, and available for each item in all warehouses combined.

- Total onhand, scheduled, and available for the specified warehouse, if a single warehouse is requested.

Open Orders By Ship Date Report (ROO 3)

The Open Orders by Ship Date Report includes:

- An exception report option that lists all orders at status S (shipped) that have not been invoiced. If you use status S to indicate shipped, then all these orders should be invoiced in a timely manner.

- A summary version that omits detail lines, but shows subtotals and recaps by status code only.

- You may also use this report to track line items and weight for orders whether open or previously shipped. This means you can list historical information regarding shipment in various summary and details formats including:

- weight shipped per truck route

- weight and number of orders per customer

- weight and number of order per ship and carrier

- number of canceled orders by ship via, truck route, and customer.

- For historical information, select the ALL ORDERS 0 EVEN IF CLOSED option.

- This report displays a recap by status code under the sub totals and final totals. The recap shows the number of lines, weight, and dollar value for each status code, making it easier to measure workload. For example, when running by truck route, it shows how many lines are open (status of O) versus filled (status of X), and so on.

- If the order is flagged for installation, the report now shows it. The word Install shows in the Truck Route column, either where the truck route would display or under it, if there is a truck route. If you run the Installation Only report, Install will not appear since all the orders are flagged for installation.

- An Installations Only version of the report has been added. This version only shows orders that are flagged for installation (Install = Y). For companies that install, the recommended procedure for running this report is as follows:

- run the Installations Only version

- sort by ship date

- sort by account number.

The report shows a sub-total by ship date (total weight per date, etc.) and then sorts by the 2nd sort option (account), and then order number.

- A Complete W/O Installs version of the report runs everything EXCEPT installation orders, use this option to generate separate open order reports to give to the different departments.

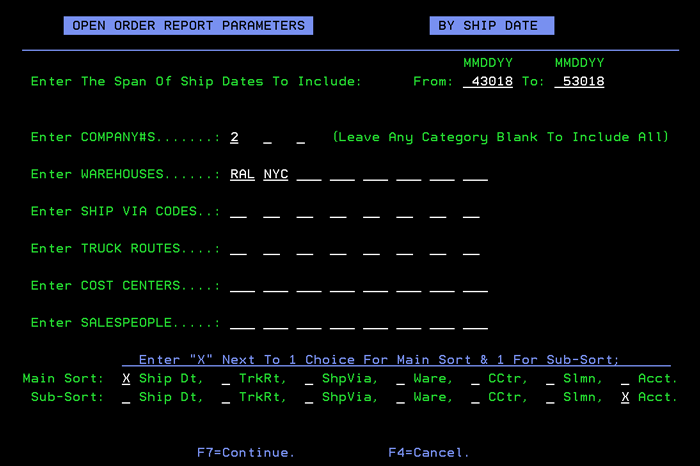

1. When this option is selected, the Open Order Report Parameters screen appears. Enter the date span, report parameters and sorting options.

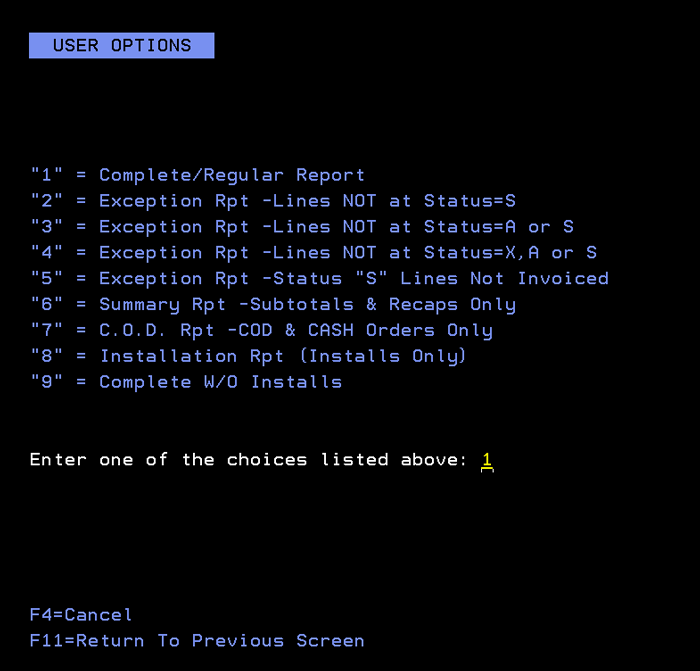

2. Press Enter to allow the system to accept your entries. Press F7 to continue. You are presented with screens that allow you to tailor the report to fit your needs. One of the screens allows you to choose the version of the report.

3. Select a report version and press Enter.

Open Orders by Supplier (ROO 7)

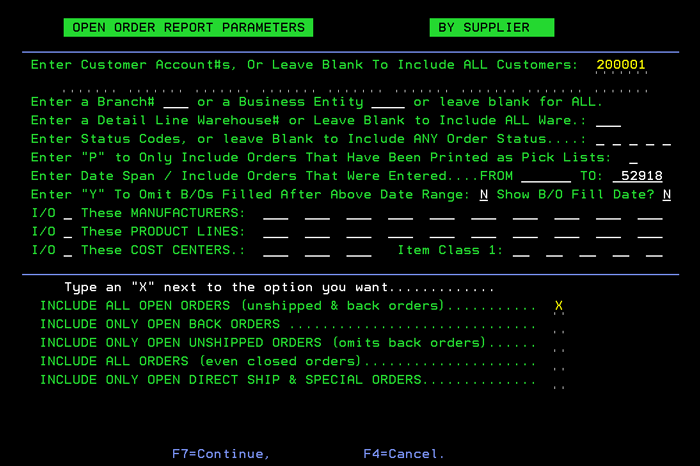

Select option 7 - List Open Orders by Supplier. The next screen to appear allows you to select parameters for the report. Make sure you enter a purchasing account number (X00001). When you enter a purchasing account number, the report lists open purchase orders. When you enter any other account, the report includes customer orders, and is limited to direct ship purchase orders.

Enter the necessary parameters, press Enter, then F7.

The next series of screens let you choose a supplier and a company to run the report for. Make these entries to access the sorting screen.

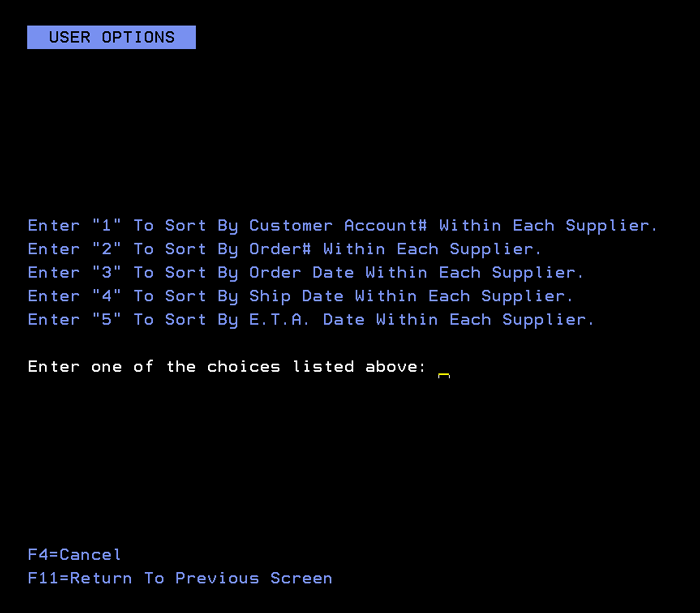

After selecting a sorting option, continue through the rest of the process to generate the report.

- The Ship Date is the date the order is scheduled to leave your suppliers warehouse.

- The ETA date is the estimated time of arrival to the warehouse or shipto destination for this order. These dates are from the Order Header.

Download Open Purchase Orders By Supplier Report

The Open Orders by Supplier report has an option to download the contents into a .CSV file for use in external spreadsheets. This enables you to analyze purchase order information by vessel, supplier, dates, etc., using Excel spreadsheets.

You can tailor the data to include or exclude fields. This process was programmed for a specific importing agent, but the file contents can be used for any importing analysis. This file can be further manipulated in Excel and supplied to your agents for their use, as well as a tool for reporting back to you.

1. On the Open Order Reports Menu, select option 7 - List Open Orders By SUPPLIER.

2. Enter the necessary parameters and press Enter, then F7 to continue through the report generation process. A series of screens allows you to generate data from a very narrow or very broad dataset.

The Omit BOs filled after above date range field helps you analyze the length of time an order has been open, relative to the date the back order was filled making the order available to be processed, instead of when the order was originally entered. For example, when requesting orders that have been open for more than 30 days, you can now further refine the request for back orders, and only show back orders that were filled more than 30 days ago. This effectively separates delays that are under your internal control from delays caused by suppliers.

If you want the report to omit back orders that were filled after a certain date, enter Y beside Omit BOs filled after above date range.

If you want the back order fill date to show on the report, enter Y beside Show B/O Fill Date? When you run the open order report, the back order fill date appears below the ship date.

3. Proceed through the screens. These screens allow you select and sort data based on various parameters including:

- Sort by customer account number, order number, or order date for each supplier.

- Inclusion or omission of claims or credits

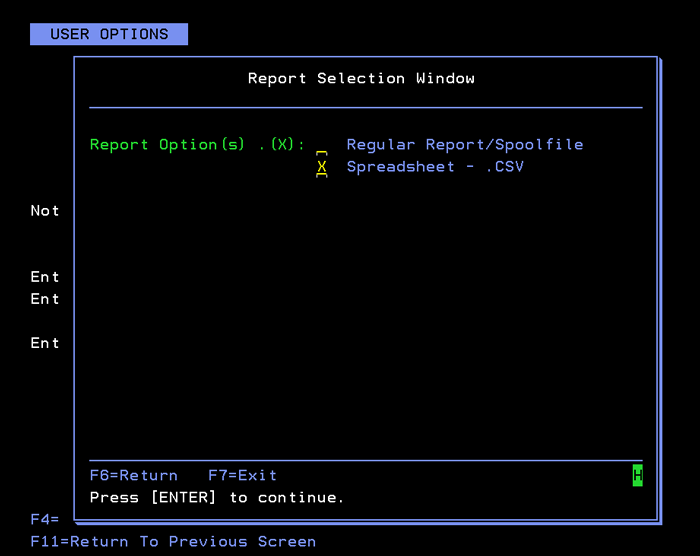

4. After going through the report parameter selection screens, the next screen you encounter gives you two options for running the report.

5. The Regular Report/Spool File option sends the report to a printer or a spool file. This is the previously available option for generating the report.

The Spreadsheet - .CSV option creates a comma separated values (CSV) spreadsheet.

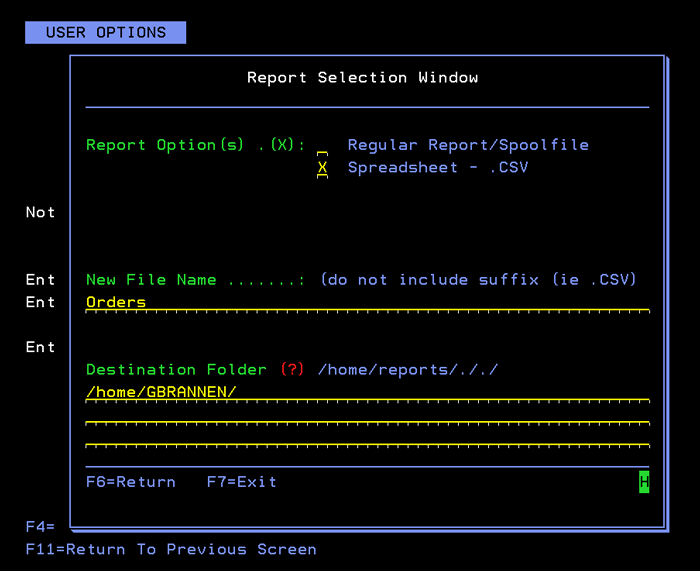

6. Select the Spreadsheet - .CSV option and press Enter. The window expands to include two more fields.

7. Assign the extracted information a name in the New File Name field. Do not include a file suffix.

8. Specify the folder and the path to it under Destination Folder.

Note: Under most circumstances, only a System Administrator can create a destination folder. To access a listing of all the established folders place a ? in the field and press Enter.

9. Make your selections and press Enter to generate the report. The report will be sent to the destination folder.

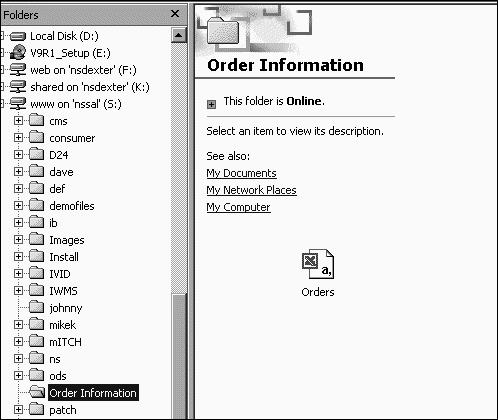

Mapping a Drive

When data is extracted, it is placed into the directory that you specify. You name the files and assign the directory. An example of a full path and file name is /home/Order Information/Orders.csv/. A mapped drive must exist between this directory and the PC where the file is to be stored.

The following steps describe how to map a drive from a PC to a AS/400.

For Windows Users

- Right click on the Start button and select Explore from the box that appears.

- Click Tools at the top of the screen and select Map Network Drive.

- In the Map Network Drive box that appears, select a drive letter that does not already exist on your PC. In the Folder box, enter \\XXXXX\Folder Name (XXXXX is the name of the Netserver running on the AS/400 and Folder Name is the folder that the extracted data is placed in.) Make sure the box Reconnect at Logon is checked.

You have now established a connection to the AS/400 folder File Name from your PC. This connection can be used to send the CVS file.

Open Orders Aging Reports (ROO 10)

This report lets you see orders by age, meaning by how much time they have been sitting in the system. These are orders that have been shipped and on which there is probably a shortage of materials (or at least the materials are not yet in stock).

Order Expediting Report for Cash/COD Orders (ROO 12)

The Order Expediting version of this report is an essential program for managing cash and COD sales. This version lists cash/COD orders that are not paid in full. This option will list any balance due - positive or negative. Recommended uses include:

- List all unpaid cash/COD orders by order number - Showing oldest first

- List all unpaid orders at status S (shipped) or A (assembled).

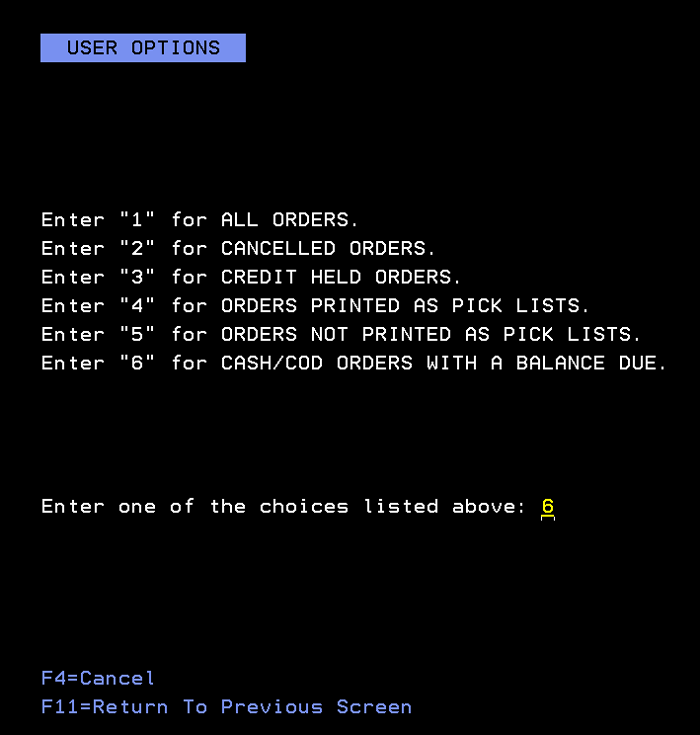

On the Open Orders Reports Menu, select option 12 - Order Expediting Reports. A series of screens takes you through the process of:

- selecting parameters for the report

- selecting a company to run the report for

- picking a sorting option

The fourth screen in the process is where the CASH/COD version of the report can be selected.

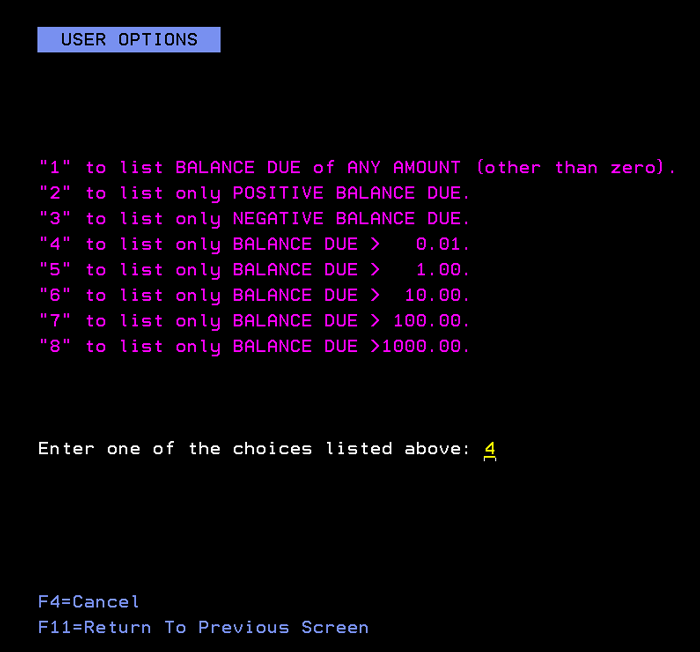

3. Select option 6. The next screen to appear lets you select a balance due amount to limit the report to.

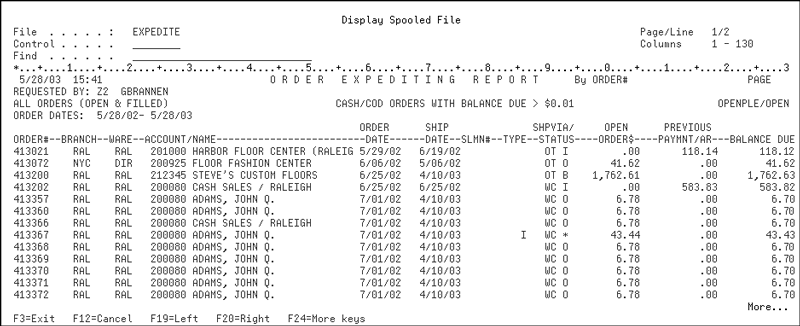

4. A sample of the report is shown below.

Order Notepad Analysis (ROO 13)

Use this report to collect data based on the messages entered on the order notepad. Only notepad entries prefixed with the @ character are included in this report.

When a Notepad analysis is run , the system finds the specified @Messages and generates the report. The messages are also stored in a Notelist file.

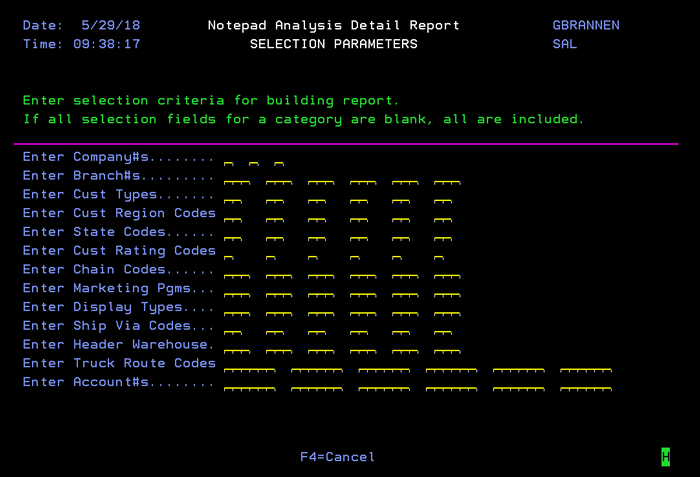

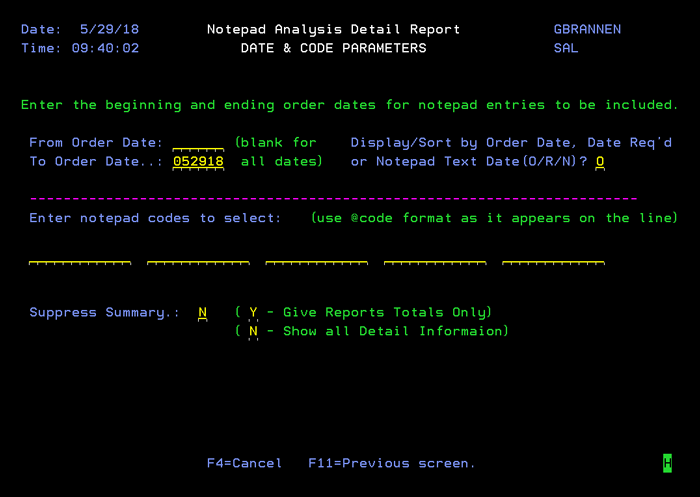

On the first screen, select the report parameters.

Select the parameters you want to include in the report and press Enter to access the following screen.

| Setting | Description |

|

From Order Date To Order Date.. |

Enter the reporting dates. |

| Display/Sort by Order Date, Date Req'd or Notepad Text Date |

Enter:

|

| Enter notepad codes to select |

Enter up to 5 @codes to select for the report. If no codes are entered, all codes are selected. The code must be entered exactly as it appears on the Notepad line. A partial code may be entered (EX: Keying @PROBLEM will select all codes starting with @PROBLEM. (@PROBLEM DEL, @PROBLEM 123, etc.)). Enter a ? in the field for a listing of all codes. The code will not appear on the list if this is the first time you are requesting it. You will need to key it in. |

| Suppress Summary |

Enter a N to show all detail lines on the report. Enter a Y to only show the totals of each code requested at the Main & Sub sort levels. |

Open Order Report for Customers (ROO 14)

These reports work in conjunction with the Output Distribution System (ODS) to automatically fax or email a report to your customers detailing back order and open order information. These reports can help keep your regular customers informed as to the status of their orders.

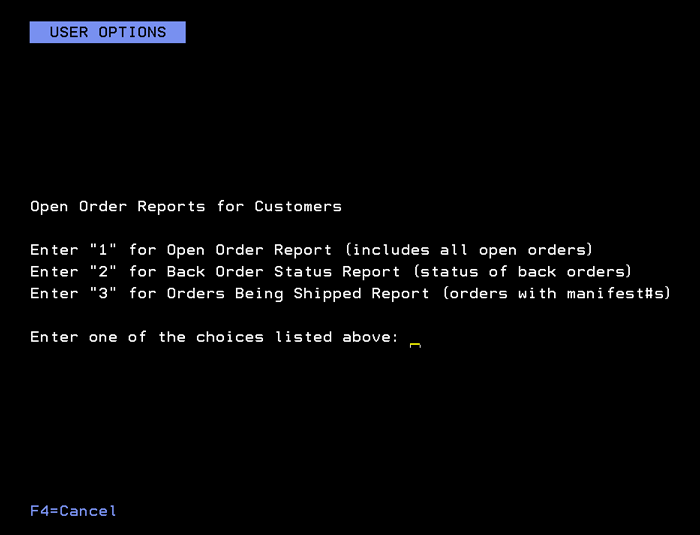

1. From the Open Order Reports menu, select option 14 - Open Order Reports For Customers.

Notes:

-

The Back Order Status report (option 2) does not include lines that have been allocated and assigned a manifest number. It is assumed that the customer already knows what has been approved to ship.

- Option 3 provides a listing of items that are allocated to stock and assigned a manifest number, and are waiting to be shipped. It is important to note that only allocated orders that have a manifest number assigned through Transportation Planning and/or Build-ATruck are included on the report.

2. The options display the following information about a customers open orders and back orders:

- Order/line number

- Purchase order number

- Ship date

- Warehouse material is being shipped from

- Items on the order

- Order quantity and UM

- Back ordered quantity and availability date

- Items that are ready to ship

3. Select to run the report for open orders or back orders and press Enter. A parameter selection screen appears.

4. Enter an I to include parameters and an O to omit them. If you include parameters, only those parameters are included. If you omit parameters, all parameters except the omitted ones will appear on the report.

5. You may include all selected customers. ODS can distribute these reports via email or fax, or you can print the reports.

6. The last parameter selection field, Business Entity, gives you the ability to limit the report to a business entity. Business entities define a business as being any combination of companies, branches, and cost centers.

7. Enter your selection parameters and press Enter. Press F7 to proceed to the next screen which presents five report sorting options.

8. Select a sorting option and press Enter. The report is sorted by the selected option. However, for the back order version of this report, within each customer the back orders are sorted as follows:

- Filled back orders

- Followed by back orders with updated status

- Followed by back orders that have not had their status updated

Holds, Quotes and Unprocessed Orders Reports (ROO 15 and ROO16)

These two reports:

- ROO 15 - Holds, Quotes, & Unprocessed Orders Reports

- ROO 16 - Holds, Quotes, & Unprocessed Orders Aging

are similar to the Open Order reports and Listings except they are only for unprocessed orders.

Unprocessed orders are orders that have not been completed using one of the order print or processing options. Unprocessed orders can consist of:

- Quotes

- Temporary Holds

- EDI orders that require review and completion

- incomplete orders (user did not fully process).

1. Access the Open Order Reports Menu (ROO). These two reports are options ROO 15 and ROO 16.

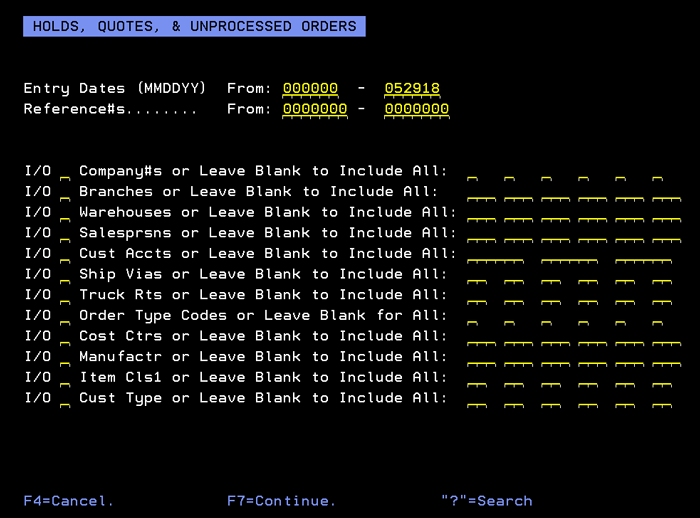

2. The two reports are very similar in terms of parameter selection. The Aging report includes aging columns such as Over 30, Over 60, etc. When either option is selected, the following parameter screen appears.

3. Choose a date range and/or a reference number range. Today's date is automatically inserted into the second date field.

If you leave these fields blank, all holds, quotes and unprocessed orders are included.

4. Next, you are presented with several sorting options. A page break on sorting level 1 is the default. In this example, each company's holds, quotes, and unprocessed orders will print separate from the other companies.

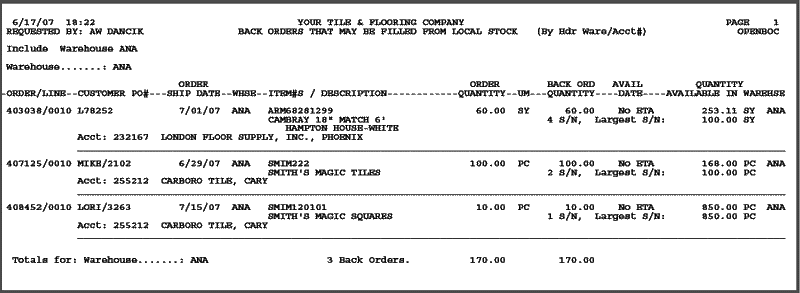

List Back Orders That Can Be Filled From Available Local Stock (ROO 17)

This Open Order report finds back orders that may be able to be filled from only local stock, or from a single serial number, within local stock.

Local stock is defined as:

- inventory that is available

- and is in the same warehouse that is on the back order.

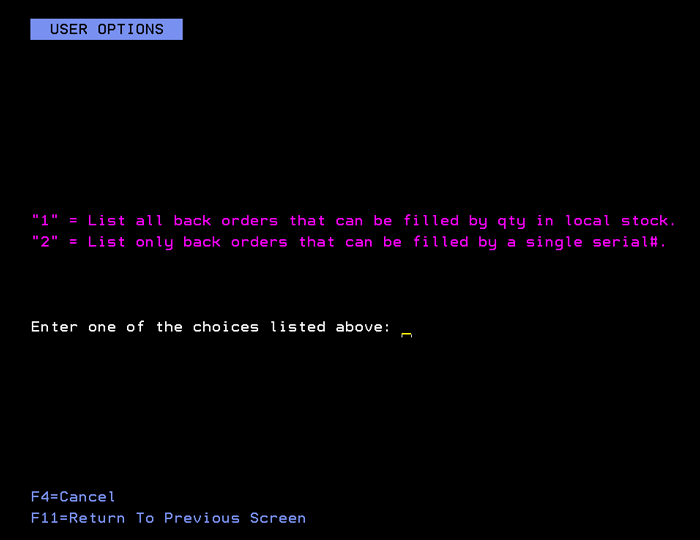

After selecting report parameters and a sorting option, you are presented with a screen that gives you two options for listing back orders.

- Enter a 1 to list the back orders that can be filled from local stock. In this situation, the report does not consider serial number requirements. It simply looks at the total quantity available.

- Enter a 2 to direct the system to only list back orders that can be filled from a single serial number, in the local stock.

An example report is shown below. In this example, notice that all of the orders can be filled by the largest serial number found in the local warehouse. The Allocation Swapping program may be used to fill these orders.

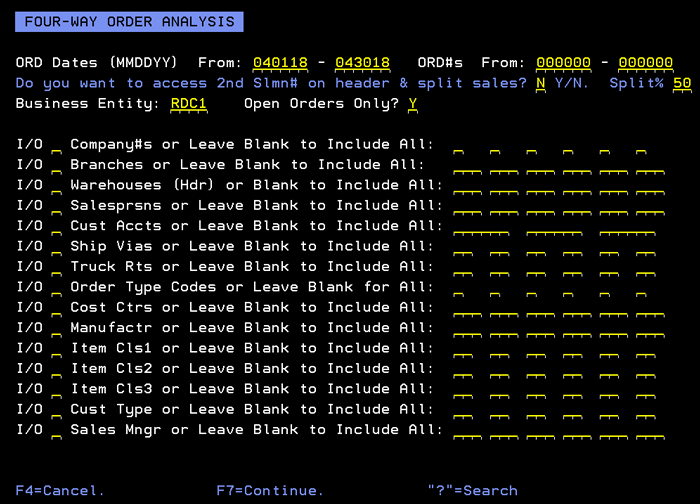

Four-Way Order Analysis Report (ROO 18)

This four-way order analysis provides a simple alternative to X by Y reports. It allows users to analyze orders and sort by many different fields including Price Promo, Cost Promo, and Fund Promo, which are not available in other 4-way or X By Y reports.

The following information for each sort category is included on the report:

- Gross Sales

- Gross Profit Dollars

- Gross Profit %

- Quantity and UM

This report enables you to include or omit data based on several parameters and then sort with up to 4 levels of sub-totals. This allows you to design hundreds of reports with up to 4 levels of sorting and subtotals.

This report adheres to the Business Entity functionality. Business Entities are any combination of companies, branches, and cost centers. Business Entities are assigned to users through the users control panel (CTRLUSER (SET 2) program). If a user is assigned to a Business Entity, it will appear in the Business Entity field. To search through all the available Business Entities, enter a ? in the field and press Enter.

If the you are running the report by salesperson, and you use the secondary salesperson feature, enter a Y in the Do you want to access 2nd Slmn# on header & split sales and the split amount in the Split% field.

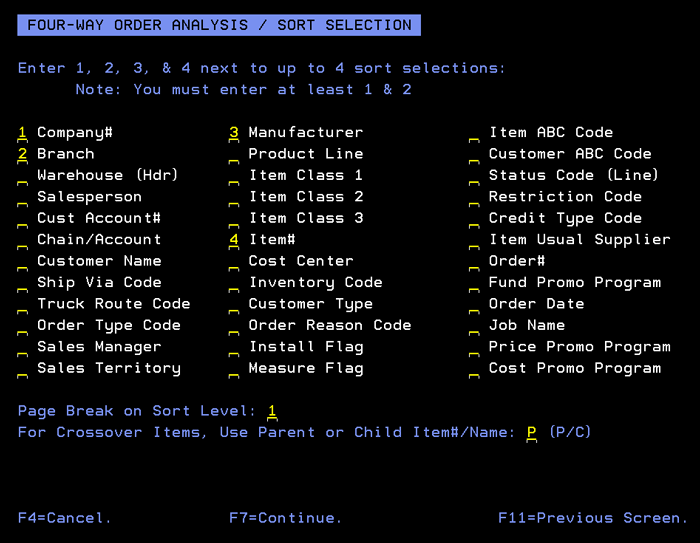

Select the parameters that you want to include in the report and press F7, then Enter to proceed to the Sort Selection screen. You can enter up to 4 sort options by entering 1 - 4 next to the fields of your choice. Each sort field represents a level of sub-totaling. You must enter at least two selections by entering 1 or 2. Enter only as many as you require.

You can specify where your page break should occur. The default page break is on your primary sort (sort 1).

If a C is entered into the For Crossover Items, Use Parent or Child Item#/Name field for child the crossover item appears on the inquiry screens and sales reporting documents.

The Crossover System, located in the Item File (FIL 2), allows you to assign two or more item numbers to the same inventory item. The two items have the same inventory, but can have different item numbers and different descriptions. The item containing the inventory is known as the parent item. The dependent items are known as child/crossover items. You can use this system to market the same product under multiple numbers and names. For example, two different cusÂtomers can have exclusive sales rights to the same item. Both customers can place orders under their own assigned item numbers and descriptions, and receive all documents (pick lists, invoices, bar code labels) with their assigned item numbers and descriptions, even though the actual invenÂtory is the same.