Receiving Inventory with IWMS

Setup

- Rack locations must be barcoded. We recommend that location labels be printed by a commercial printer.

- RF terminals must be installed.

- Zebra barcode printer for labels, AFPDS Laser Printer for printing 8 x 11 TAGS (Optional, but highly recommended).

- Set-up storage codes to have the program suggest warehouse locations for directed putaway. This requires the IWMS Location files have capacities and pick/putaway sequences entered. For more information, refer to Location File.

- Get the UPC codes from suppliers to allow scanning of physical cartons during receiving. The UPC codes can also be entered from the product bar codes if you cannot get them from the manufacturer.

Receipts Pre-Check

The first option on the RF menu, Receipt PreCheck, allows you to double check to ensure that the correct label is being used on the received inventory.

- Prior to moving inventory off the loading dock and into the storage areas, scan the label and then the inventory to ensure you have a match.

- Scan the receipt and line number on the label. Then scan the inventory bar code label. The system confirms that the scanned label and inventory are a match.

Steps to Receive Inventory

- Move receipts to the Pre-Receipts file. Do this via option 1 - Enter Receipts (pre-receive/no posting) on the Inventory Receipts & Back Order Fill Menu (INB) menu.

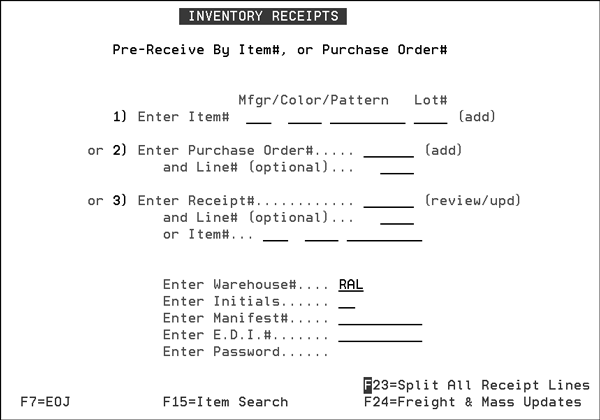

- The Inventory Receipts screen appears. Enter a receipt or manifest number.

- The next step is to split the inventory on the receipt to efficiently make pallets. This can be done in two ways:

- Press F23 - Split All Receipt Lines on the Inventory Receipts Screen. This splits all the receipts for any entered parameter. The first screen to appear in this process allows you to select a warehouse.

- Using the List Receipts Program (INB 002)

- When this option is used the Receipts Listing Parameters screen appears. Enter a manifest or receipt number.

- Press F23 - Split All Receipt Lines. The following screen appears.

- Press Enter to split all the receipts in the Pre-receipts file.

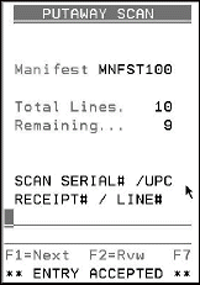

- After splitting the lines, scan the items into your inventory system. This is done via option 2 - Putaway Screen on the RF menu.

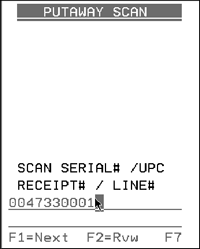

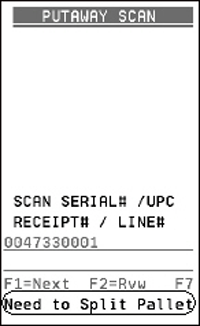

- Scan either a serial number, UPC code, or receipt number/line number. Depending on your Warehouse Settings, if the receipt has not been split, the following error message appears.

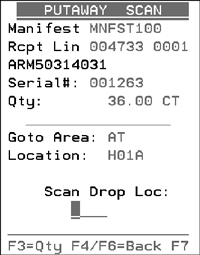

- The screen refreshes to show information about the receipt.

- Move the pallet/roll to the desired or suggested location and scan the location label. The system does the following:

- Assigns inventory to the location in the pre-receipts file

- Flags the receipt/line as Checked-In

- This shows Checked-In on the Pre-Receipts entry screen

- This shows Checked-In on the Pre-Receipts listing

- Writes a transaction record to the Task History Log

- You are returned to the scan a serial number, UPC, receipt/Line.

- When a receipt line is scanned, the system checks the Maximum days ahead to allow for a crossdock opportunity field in the Warehouse File Maintenance to see if the inventory can be sent directly to a staging area to fill a back order. If so, the system suggests the staging area for the outgoing order.

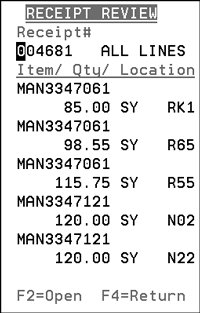

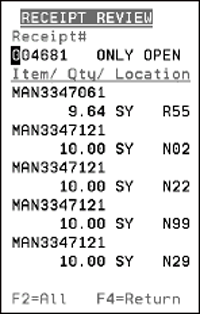

- Press F2 to display a receipt review screen.

- 11. Pressing F2 on the Receipt Review screen, toggles the display between all the lines on the receipt and only the open lines, those that are not checked in, on the receipt.

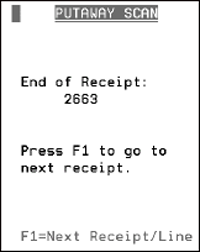

- When you have completed a receipt, the End of Receipt Screen displays.

- Press F1 to display the first line of the next receipt number in the Pre-Receipts File. Press F7 to end the job.

- Move the pallet/roll to a staging area or rack location and enter or scan the location in to receive to that location. The system performs the following:

If you want to limit this action to certain receipts or manifests, enter them and press Enter. If you leave all the fields blank the following screen appears.

Find the receipt you want to split and enter an S next to it.

Splitting receipts helps keep track of inventory and to improve inventory accuracy. For example, if a receipt consisting of five pallets is not split, when the operator scans and puts away the first pallet all five pallets are now shown in that location even though they may not be. IWMS can be directed to only receive split receipts via the setting Prevent RF Putaway if receipt line needs to be split to pallets under the Receiving Options of page one of the Warehouse Settings (WM2 1).

- The inventory is assigned to the location in the Pre-Receipts file

- The receipt/line is flagged as Checked In

- A transaction record is written the Task History Log.