Manufacturer File - FIL 4

Manufacturer File Sales Analysis Screen

Manufacturer File Special Instructions Screen

How the Manufacturer File ties into Receiving Inventory

The Manufacturer File contains information about each manufacturer of products that you sell. A manufacturer record usually represents the corporate name of a manufacturer, but can also represent a brand name, a private label, or a generic product category that has no actual manufacturer, such as marble or granite.

|

Field Name |

Description/Instructions |

|

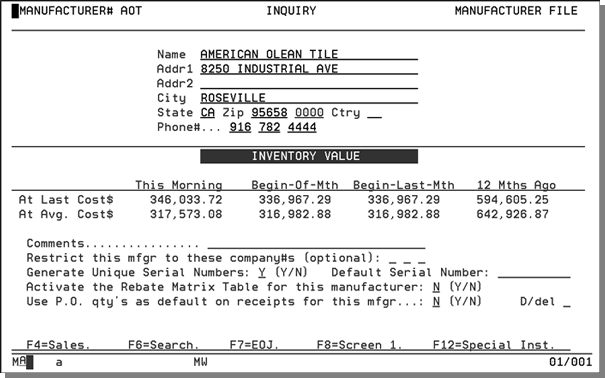

The inventory value statistics are shown only when you're in the inquiry or update mode. |

|

|

At Last Cost $ |

The total value of inventory, valued at last cost, for all items in stock for the manufacturer at the time specified in each column. |

|

At Avg. Cost $ |

The total value of the inventory, valued at average cost, for all items in stock for the manufacturer at the time specified in each column. |

|

This Morning |

Inventory values when Night Jobs was last run. |

|

Begin-of-Mth |

Inventory values when the last end-of-month procedures were run. |

|

Begin-Last-Mth |

Inventory values when end-of-month procedures were run one month before the last closed month. |

|

12 Mths Ago |

Values when end-of-month procedures were run twelve months before the last end of month closed. For example, if the current month is January, then this column would refer to the inventory values at the beginning of last January. |

|

Restrict this mfgr to these company#s |

Up to three company numbers to which you want to restrict this manufacturer. This feature is mostly for licensees of the ROGUE (Remote Office and Guest User Environment) system. It secures users of one company from viewing products of another company. |

|

Generate Unique Serial Numbers? |

Enter Y to generate unique serial numbers. The Receipts and Back Order Fill System (option 6 from the Inventory Control Menu) automatically assigns a unique six-digit serial number each time a receipt is entered. For more information on this feature,

refer to How the Manufacturer File ties into Receiving Inventory.

|

|

Default serial number |

Enter a default serial n umber here for the Receipts and Back Order Fill System to automatically insert for each receipt of this product. For more information on this feature,

refer to How the Manufacturer File ties into Receiving Inventory.

|

|

Unique S/N Prefix: Suffix: |

These fields allow you to assign a one or two character prefix and suffix to serial numbers automatically generated during the receiving process. Unique serial numbers can aid in identification of inventory transactions, and improve bar code scanning processes. These fields along with the field Generate Unique Serial Numbers work in conjunction with the receiving application (INB 1) to assign unique serial numbers to inventory at time of receipt. For example if the Prefix is set to A and the Suffix is set to R, unique serial numbers will be generated for all inventory receipts of products from this manufacturer, and those serial numbers will be generated in the following format: AnnnnnnR - Where nnnnnn represents a unique six-digit number. This format will apply to all products for this manufacturer, unless overridden in the Product Line File (FIL 12), or overridden on individual receipts. |

|

Activate the Rebate Matrix Table for this manufacturer |

Enter Y to activate the Rebate Matrix Table for the manufacturer you selected. Enter N if you do not want this manufacturer to activate the Rebate Matrix Table. |

|

Use P.O. qty's as default on receipts for this mfgr |

Enter Y if you want the receiving program to automatically assume the quantity on the purchase order being received when a purchase order number is specified. As the receipts are entered, the Quantity and U/M fields are automatically filled with the quantity and unit of measure on the purchase orders. This field should be set to Y for manufacturers who consistently ship the exact quantities ordered. This field is ignored for rolled goods, as the exact quantities per roll must be entered. This feature can significantly reduce the time it takes to enter receipts. The default is N. |

|

D/Del |

Enter D to delete this record. This field requires a high-level password. We do not recommend deleting records, because you might also delete historical statistics for a manufacturer. |

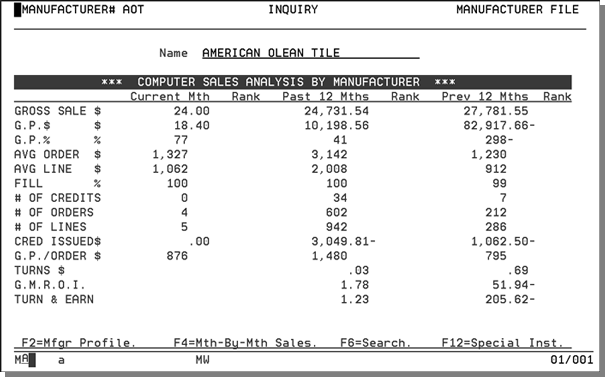

Manufacturer File Sales Analysis Screen

Month-by-Month Sales Analysis Screen

On the Manufacturer File Profile screen, press F4.

|

Field Name |

Description/Instructions |

|

Gross Sale $ |

The gross sales amounts for the periods shown. |

|

G.P. $ |

The gross profit amount. |

|

G.P.% |

The gross profit percentage. |

|

Avg Order $ |

The average order dollar amount. |

|

Avg Line $ |

The average dollar value of every line ordered for this manufacturer. |

|

Fill% |

The percentage of order taken that was filled based on invoicing. |

|

# of Credits |

The number of credits issued for this manufacturer's items. |

|

# of Orders |

The number of orders taken for this manufacturer's items. |

|

# of Lines |

The number of lines sold for this manufacturer's items. |

|

Cred Issued |

The dollar value of credits issued for this manufacturer's items. |

|

G.P./Order $ |

Average gross profit dollar amount per order for this manufacturer's items. |

|

Turns $ |

Shows the inventory turns based on dollar value. The inventory turns are calculated as follows: Total Cost of Sales Inventory Value Turns = Average Onhand Inventory Value |

|

GMROI |

The gross margin return on inventory investment ratio for this manufacturer. The GMROI is an industry standard statistical index calculated as follows: Gross Profit Amount GMROI = X 100 Average Onhand Inventory Value |

|

Turn & Earn |

The turn and earn ratio for this manufacturer. Turn and earn equals the turns multiplied by the G.P.%. |

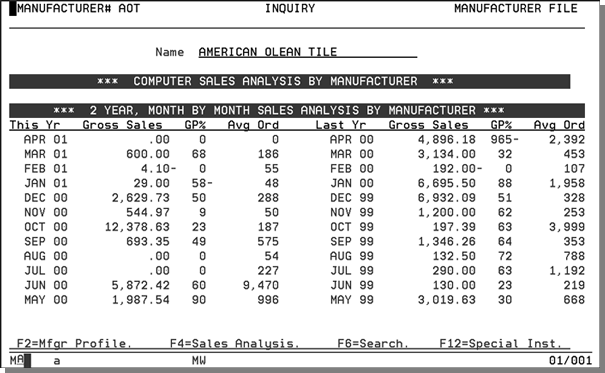

Month-by-Month Sales Analysis Screen

On the Manufacturer File Sales Analysis Screen, press F4.

|

Field Name |

Description/Instructions |

|

This Yr |

The months of the year to date. Months shown are trailing months, not fiscal year months. |

|

Gross Sales |

The gross sales for each month. |

|

GP% |

The gross percentage profit for each month. |

|

Avg Order |

The average order amount for each month. |

|

Last Yr |

The 12 months prior to the months shown in the first column. |

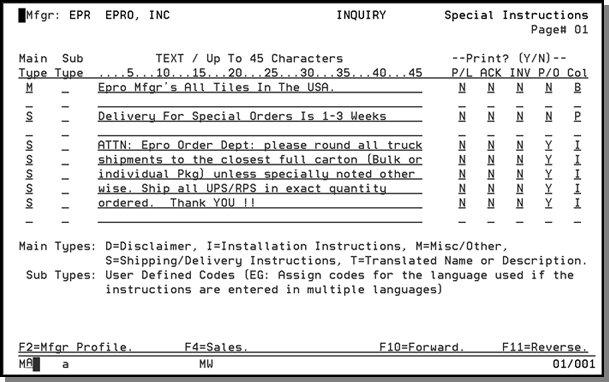

Manufacturer File Special Instructions Screen

You can enter special instructions about a manufacturer and notate those that should be printed on either an invoice, pick list, order acknowledgment, purchase order, or reorder report. You can enter up to ten lines of text, 45 characters per line, per page, and up to 20 pages.

1. On the Month-by-Month Sales Analysis Screen, press F12.

2. Enter code in the Main Type column as described on the lower portion of the screen.

3. Enter a language code in the Subtype field to specify text to appear in a specific language, such as F for French or I for Italian.

4. Enter up to 45 characters in the Text field.

5. Enter Y (yes) or N (no) for whether to print on pick lists, order acknowledgements, invoices, and purchase orders.

This screen is also available in the Item File and the Product Line File. A slightly different version of this screen is available in the Billto File. General instructions that pertain to an item or product line should be entered in those files.

The manufacturer's special instructions print on the specified documents, under the last consecutive item number within that manufacturer. Any special instructions with no sub-type code, such as language, only print for customers with the same language code. Lines coded with Main Type P print on Reorder Reports.

All special instructions entered via F12 in either the Billto, Item, Manufacturer or Product Line Files can be printed in a separate listing. You can use the listing to proofread the instructions or as a reference. The listing can include all or specified types and sub-types of instructions. For example, you can print installation instructions separately, or you can print only the French entries. You can run this list, for example, for specific items or product lines. See the second page of the Master File Listings Menu.

The following table describes the fields on the Manufacturer File Special Instructions screen.

|

Field Name |

Description/Instructions |

|

Main Type |

The main type options listed at the bottom of the Special Instructions screen are:

|

|

Sub Type |

Sub types represent the language in which the instruction is written. Leave blank if the instruction is applicable to all customers. Enter a customer language code to limit printing of the line for customers with that language code. For example, an instruction with sub type F prints only if customer is coded for French. |

|

TEXT |

Enter special instructions (up to 45 characters). |

|

Print? |

Specify where this information prints: on the picklist, acknowledgement, invoice, or purchase orders. Enter Y to print. Enter N not to print. |

|

PL |

Pick list. |

|

ACK |

acknowledgment or quotations. |

|

INV |

Invoice to customer. |

|

P/O |

Purchase order to supplier. |

|

COL |

Use this field to color code Product Knowledge information on the Customer Service Product Knowledge Screen which is accessed via F12 within Order Entry. These color codes are not carried over into DNav - Online (Decor 24) Product Knowledge tab.

The possible values are:

These color codes control each individual line on the Order Entry Product Knowledge Screen. We recommend that you develop a company-wide strategy concerning which colors should relate to which types of information. For example, substitute items could appear in pink, important product disclaimers in red, or installation instructions in white. The I (invisible) code should be used for any information that should not be viewed by customer service during Order Entry. |

How the Manufacturer File ties into Receiving Inventory

Receiving with Default Serial Numbers

You can use the receiving system to assign default serial numbers by manufacturer and by product line. When you use the Pre-Receipts system, the default serial numbers are automatically inserted in the Serial Number field during receiving. You can use this feature in many situations:

- For items, such as installation materials, that can be set up as serial number items, primarily for dynamic tracking by location. The default serial number could be REG, indicating regular. You would only override the serial number to denote something unusual, such as a change in packaging or an imperfection in a specific shipment.

- For items that are manufactured to certain specifications or master shades, the default serial number could be the normal or master shade designation, and it would only be overridden at receiving time for off shade or off specification material.

Enter default serial numbers in either the Manufacturer File - FIL 4 or the Product Line File - FIL 12. The Product Line File overrides Manufacturer File entries.

When receiving, the default serial number is shown for the applicable manufacturers or product lines. You can override the default serial number on the receiving screen.

Receiving with Unique Serial Numbers

You can use the receiving system to automatically generate and assign unique serial numbers to each incoming receipt. The program assigns a six-digit number as the serial number. The serial numbers are assigned in ascending sequence, but each serial number is verified as being unique before it is assigned. If the program finds that a serial number that has already been used anywhere in the system, it checks subsequent consecutive numbers until it finds a unique number. You can activate this feature for specified manufacturers and product lines. You can use it in following situations:

- For items that are sensitive to age. You might want each receipt to be separated in inventory, so that you can sell products with older serial numbers first. You can use the receipt date as the serial number. However, using the unique serial number feature has two advantages over using the date. First, The customer doesn't see the date; you might not want your customer to know how long a product has been in the warehouse. Second, the unique serial number is inserted automatically, eliminating the need to manually enter a number in the serial number field.

- For items that come from the manufacturer with unique serial numbers that are too cumbersome to use, and have no actual meaning required for day-to-day operations, for day-to-day operations. The system-generated unique serial number accomplishes the main purpose of separating the inventory, yet offers an easy-to-use six-digit number instead of the manufacturer's number. In addition, you can enter and store the actual manufacturer's serial number in the Other Ref# field on the Receipts Entry Screen. Consider this feature for carpet with cumbersome roll/serial numbers, and for ceramic products from manufacturers with unreliable shade designations.

To activate the unique serial number feature

- The system administrator must select the appropriate options in the System Wide Settings program on the System Settings Menu. This includes the entry of any unusable ranges of serial numbers. Entering an unusable range of serial numbers instructs the program that assigns unique serial numbers to skip those numbers. This is helpful if you have a set of numbers that you intend to assign manually in specific situations.

- Enter Y in the Unique Serial#s? field in either the Manufacturer File or Product Line File. Product Line File entries override Manufacturer File entries.

Once activated, the receipts entry program automatically displays the next unique serial number and a message indicating unique serial numbers will be assigned.

Associated Files

Manufacturer’s Rebate Matrix Table - FIL 32

X By Y Manufacturer Rebates (RSA 210)

Create Excel Sales File for Manufacturers - SYS 313