Stock to Stock Transfer Rules

This file, along with the Stock to Stock Safety Transfer Safety Days and the Stock to Stock Branch Transfer Reorder Parameters files are used to set -up the Stock to Stock Transfers Reorder Report. The Branch Reorder Report automates the process of calculating and entering transfer orders.

Prior to the introduction of these files and the Stock to Stock Transfers Reorder Report in 2012, branch managers or purchasing agents had to manually research inventory needs and then enter the transfer orders.

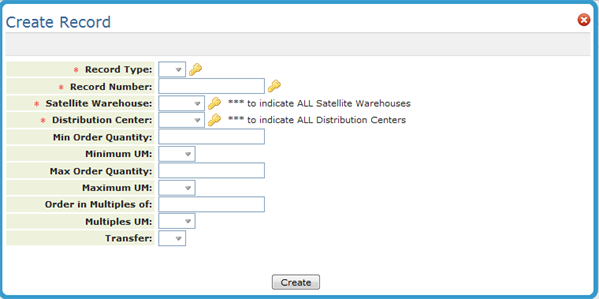

The Stock Transfer Report uses this table to adjust quantities on order lines. These settings are accessible by creating a new record or by using the Filters functionality to select information to display. The Create Record window is shown below.

The settings with a key icon are required and are used for system functionality such as searches.

| Setting | Description |

| Record Type |

Identifies this record as being for one of the following:

|

|

Item Class Manufacturer Product Line Price Class Item |

This setting changes in relation to what is entered in the Record Type setting. Enter a specific value such as a manufacturer or item number. |

| Satellite Warehouse Distribution Center |

The Satellite Warehouse is the branch warehouse that is receiving the Transfer Orders. The Distribution Center is the warehouse that will be generating and filling the transfer orders. Warehouses codes are created and maintained in the Warehouse File (menu option FIL 8). The record must include a distribution center and satellite warehouse combination. Wildcard Enter *** in either the Satellite or Distribution Center settings to enter rule sets that apply to general warehouse combinations.

|

| Min Order Quantity Minimum UM | Enter the minimum quantity and its associated unit of measure to transfer. |

| Max Order Quantity Maximum UM | Enter the maximum quantity and its associated unit of measure to transfer. |

| Multiples to Order Multiples UM |

Enter a quantity, if any, representing the multiples in which you want to order. For example, an entry of 1 CT indicates you must place an order in full cartons. An entry of 1 PA indicates you must place order in full pallets. This field is separate from the minimum quantity. For example, you may have a minimum quantity of 1 PA, but multiples of 1 CT. This means that the reorder programs will order at least 1 PA when the product is needed, but if more than 1 PA is needed, it will round additional qty to cartons. |

| Transfer |

|