Future Orders

Future Order and the Order Header

Guidelines for Using This Feature

Overview

Future orders, also referred to as forward orders, are defined as back orders that are entered with a long range future date and placed against inventory that has not yet arrived into stock. Future orders can be allocated against a quantity that appears in the Scheduled column and that also has a future date. This is material currently on order from your supplier. However, future orders can be entered for planning purposes without a purchase order having yet been issued.

This feature of the Inventory System can dramatically improve the effectiveness of your sales staff in turning your inventory if used consistently. It is primarily designed for managing orders for items that are imported or have unusually long lead times. Basically, a future order is a back order that is not to be immediately filled. It is identified on all screens with an F status code.

Designating a Future Order

Complete these steps to designate an order as a future order:

- Enter F in the Type field of the Order Entry System.

- Enter the date you expect the customer to receive the material in the Order Date field, on the upper right side of Header Screen, as well as in the Date Required field. This date should fall after the date of the ETA of the incoming shipment which is planned or on order. That will ensure that the customer's order follows the purchase order on the Stock Card Screen, which clearly indicates the customer order is against that specific incoming stock, not against any more current purchase orders.

The order is processed using the same procedure as a regular customer back order.

After an order is posted, you can use the Update Order Status and Shipping Data program to adjust the status and dates for the customer order and the purchase order. When a future order is within a date range you consider to be current, you can update the status F to status B, K, or D as needed.

This function is similar in many ways to designating an order as a back order. The difference relates to your type of business and the type of orders you service. If you deal mostly with local suppliers and sell mostly orders from stock, using the B (back order) code is more appropriate than the F (future) code. If you are primarily an importer dealing with long lead time orders, use of the B and F codes is more appropriate.

Future Order and the Order Header

The fields identified in the figure below have an impact on Future Orders.

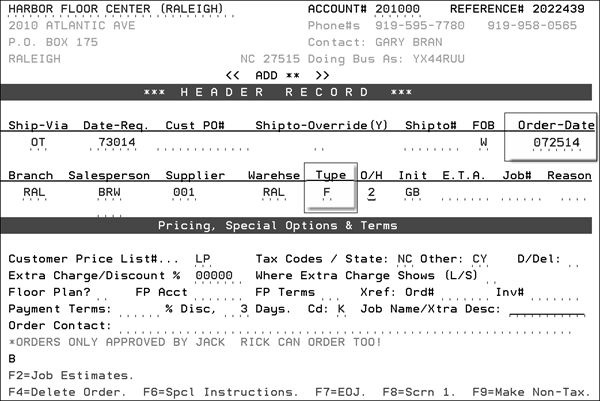

Green Screen

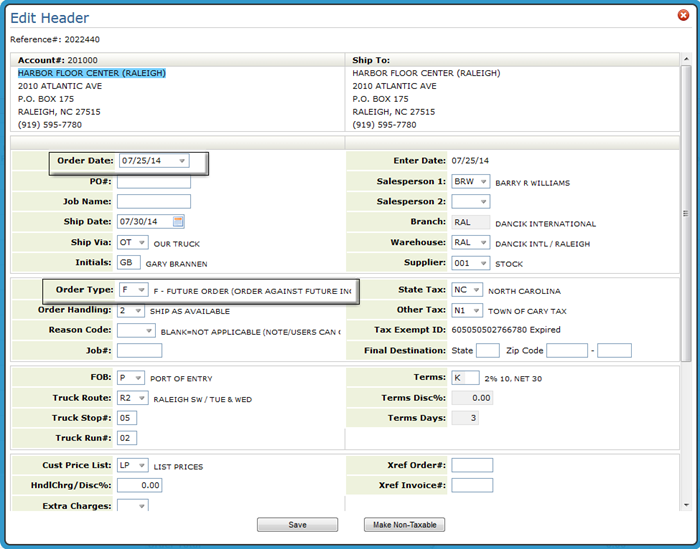

Navigator

- Order Date -The date entered in this field is the effective date for allocating inventory that appears on the Inventory Inquiry Stock Card Screens. If the order is being placed against future arriving stock, consider using code F in the Type field to indicate future orders and using the intended ship or pickup date as the order date. Although the material is still allocated immediately, the Detail Inventory Stock Card Screen shows the order as allocating from future stock rather than from current stock. The system also retains the date that an order was placed separately from the effective order date. If you are entering a temporary hold order, changing the order date extends the hold until 2 night job cycles after that date.

- Order Type - F - Future/Forward Orders - This code designates that the order is for stock that has not yet arrived. When entering code F, you should also enter an order date that coincides with, or is just after the future arrival date of the stock.

Guidelines for Using This Feature

In order to effectively use the future order feature, consider these guidelines:

- Keep ETA dates for purchase orders and order dates for future orders up-to-date. You can use the Update Order Status and Shipping Data program. Order dates for future orders should follow the ETA Dates of the purchase orders against which the future orders are allocated.

- Use the Reorder Report option that displays customer back orders. Future orders have a status of F. You can then easily determine the right time to place purchase orders to cover future orders.

- Use the Additional Shipping Data Screen of the Update Order Status and Shipping Data Program to notate a vessel name for imports. You can notate the vessel name on purchase orders and the customer future orders allocated against the material on that vessel. By notating the vessel name, you can then use the Update Shipping Data by Vessel Name program, which with a single entry, can update dates and status of all purchase orders and related customer future orders on that vessel.

- If you use the Vessel Name field, you can benefit from the following two reports:

- The Open Orders By Vessel Report lists all orders or purchase orders by vessel.

- The Inventory Reorder Reports, Version 6, for Importers shows current stock on hand and available, and matches future and back orders against incoming purchase orders by vessel. If three vessels of a popular item are due to arrive, each spaced one month apart, the report can show the quantity of that item on each vessel, followed by all of the customer orders allocated against each vessel. In effect, each vessel is displayed with its own inventory, showing what remains available for each vessel and ETA date.

- If a vessel is changed or delayed, use the Update Shipping Data By Vessel program to update files easily.